unidim XL

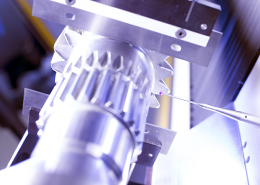

Versatile machine, unidim XL is designed to provide best accuracy in the most severe operating conditions for larger shaft up to 800mm

![]()

![]()

![]()

- Multi-sensor measuring machine (Ø, Lg, θ)

- Designed for workshop use

- Versatile, robust, reliable and fast

- Integrated collision protection

- Equipped with a safety light barrier for easy access

- Integrated sealed and air-conditioned cabinet

- Easy, on-line or workstation programming

- Real time SPC results displayed, integrated or network statistical processing (option)

- External calculation software for specific measurement purposes

technical features

integrated functions

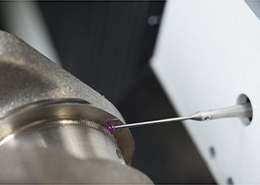

Specially-designed probe and software for cam-shaft checking applications, measuring:

- Cam base diameter

- Programmable lift error measurement on up to 6 different angular zones

- Timing and inter-cam angles

- Maximum lift and rotation step error

- Calculation of measured characteristics in relation to part referencial

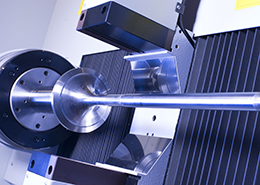

Specially designed probe and software for crankshaft checking applications:

- Crank-pin diameters measurement (dynamic)

- Stroke and half-stroke measurement

- Crank-pin face runout measurement

- Angular positions of crank-pins

native measurement functions

conditions

CALIBRATION

Automatic on integrated

calibration zone

Depending on time and/or

temperature

Automatic on integrated

calibration zone

Depending on time and/or

temperature

POWER SUPPLY

230 or 400 VAC, 50hz

OPERATING CONDITIONS

Humidity ≤70%

Temperature 15°C – 40°C

NOISE LEVEL ≤70dB (A)

MEASUREMENT PRINCIPLE

special devices

Loading system (retractable) enables

Loading system (retractable) enablesa high level of comfort and safety for heavy part handling

Double ball center point

Double ball center pointexample of applications